Quality guarantee

CONSTANT CONTROLS

For the Group, maintaining high quality standards means fully satisfying the requirements of professionals for whom our product is a fundamental work tool. This is why in addition to complying with international standards for our products, we also run constant controls throughout the entire production cycle.

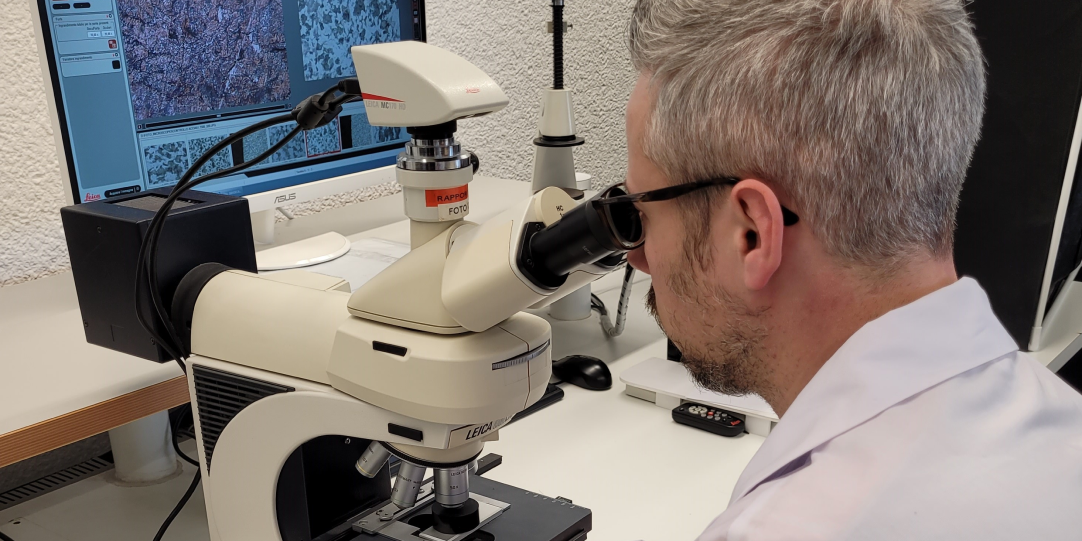

OUR QUALITY DEPARTMENT

Thanks to tools for analysing the raw materials used in production, our Quality Department, which employs professionals with high technical skills, tests all materials to ensure maximum performance of our products and maximum safety for our users.

OUR QUALITY DEPARTMENT

Thanks to tools for analysing the raw materials used in production, our Quality Department, which employs professionals with high technical skills, tests all materials to ensure maximum performance of our products and maximum safety for our users.

The quality of our products is certified by:

CISQ/ICIM

Quality Management System UNI EN ISO 9001: 2015 defines the requirements necessary for continuous process improvement based on risk analysis, giving added value to maintaining the effectiveness and efficiency of production phases, optimising the management system while maintaining high standards of customer satisfaction.

Istituto Italiano del Marchio di Qualità – I Verband der Elektrotechnik Elektronik Informationstechnik – D

TÜV

Beta is proud to carry the prestigious TÜV mark since 2018, after passing the stringent controls of the EK5/TA5 test protocol.

The EK5/TA5 protocol consists of 31 well-defined construction characteristics, stringent static tests and dynamic behaviour tests. Other tests define resistance to high and low temperatures, the duration of marking over time and resistance to corrosion.

These goals have been achieved thanks to the expert design, meticulous construction and stringent controls implemented by Beta in the production of its TÜV marked products.

Organizzazione per la Sicurezza degli Abrasivi (O.S.A.)

ENEC

“Conflict Minerals” Policy

BM does not purchase minerals directly from mines and foundries, however it requests its suppliers to avoid the use of “conflict minerals” (Tantalum, Tin, Gold and Tungsten), to discourage the use of minerals, which may be traded to fund or support armed groups from geographic areas rich in natural resources affected by conflicts or at high risk of conflict, such as the Democratic Republic of Congo and neighbouring countries.